Cleaning critical surface

J trading is an agent in Japan of Foamtec International WCC. Foamtec International WCC is contamination control professionals to improve particle control in clean rooms by solving surface contamination challenges, which head office is located at Texas in USA and also have sales office at California, plant in Thailand. Most of customers are semiconductor manufactures and medical devices manufactures,which have clean rooms.

| Office and plant | Texas Head office California Branch Thailand plant |

|---|---|

| Main customers | World wide famous semiconductor plants Medical (catheter) producers |

Product list

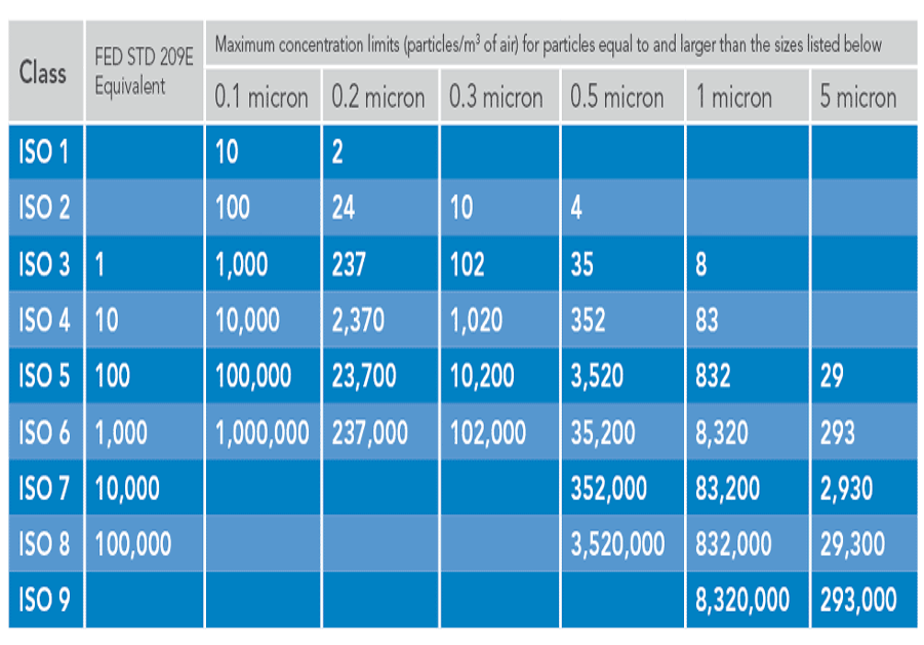

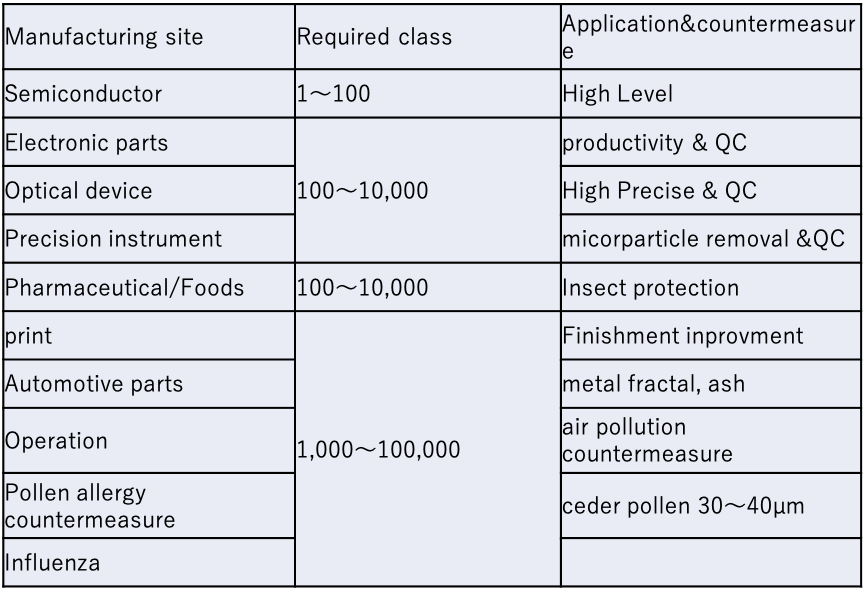

Clean room classification & target industries

|

|

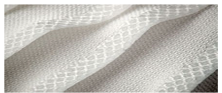

MiraWIPE

Microwiper for ISO Class3 Clean roomHT5790S & 5790SM

MiraWIPE® is a cleanroom microfiber wiper constructed from a continuous filament micro denier, polyester/nylon textile that enhances absorbency and particle contamination removal versus traditional polyester wipers.

Woven from an abrasion resistant fabric to minimize shedding of particulate matter from the face of the wiper. Sealed edge construction and proprietary washing process ensure compatibility with ISO Class 3 cleanrooms.

Microfiber construction offers excellent cleaning efficiency allowing MiraWIPE® to remove trace residues from Vacuum Chambers and disinfectant residues from Medical Device and Pharmaceutical cleanrooms. MiraWIPE®’s non-symmetrical micro fiber structure allows it to scrub microbial bio-films and sporicidal residues making it ideal for disinfection procedures.

Advantages

- Unsurpassed Cleaning Efficiency. Star shaped microfiber leads to enhanced removal of particles, metals, and organics from cleanrooms.

- Delivers Cleaner Tools. Engineered fabric resists abrasion and snagging to prevent in-use fiber and particle shedding.

- ISO Class 3-5 Compatible. Unique edge seal process maintains sealed edge integrity even during heavy duty wiping.

- VOC Free Cleaning. Interstitial fabric design allows DI water to replace solvents such as IPA in equipment cleaning applications.

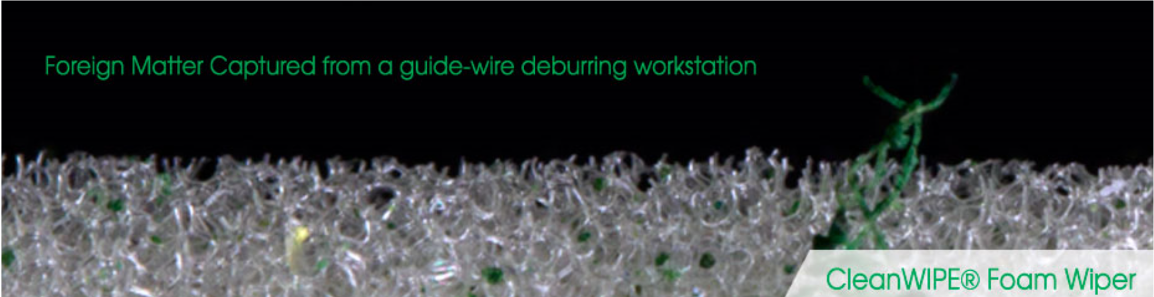

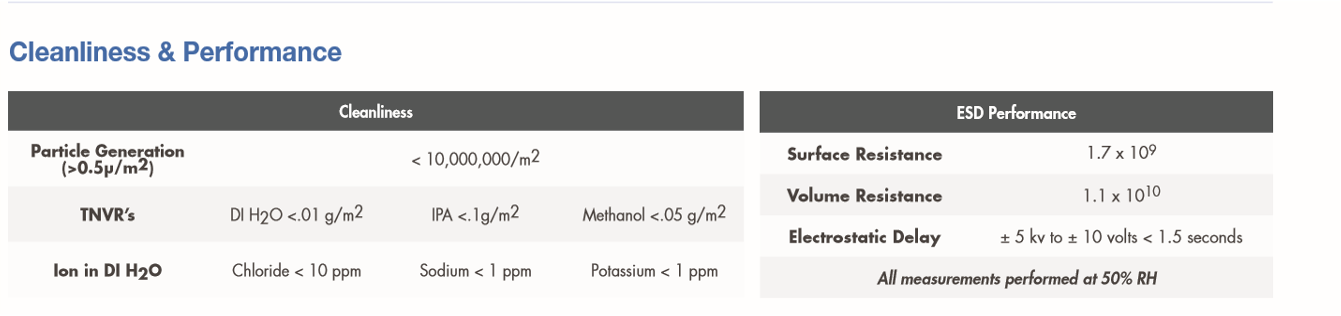

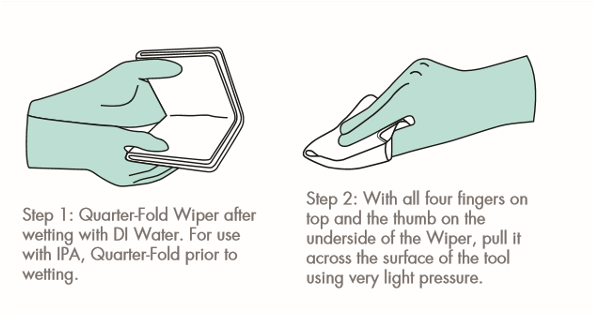

CleanWIPE

Urethan wiper for Cleanroom HT4203 2.8mmTx15㎝x15㎝

CleanWIPE is a cleanroom foam wiper designed to reduce foreign particulate contamination in class III medical device manufacturing facilities. The unique polyurethane open pore foam has flexible, abrasion resistant, finger like struts that extend off the face of the wiper enabling operators to dramatically increase both wiping efficacy and efficiency. The unique open cell construction results in very large surface area which enables operators to efficiently clean particulate contamination sized up to 750 microns. The large surface area in combination with the soft, flexible foam allows the wiper to conform to work surfaces, tooling and class III devices for complete cleaning. CleanWIPE’s sponge like properties enable operators to fine tune the amount of IPA delivered to a surface in order to clean difficult to remove materials such as epoxies and silicones much more efficiently. CleanWIPE is laundered with a proprietary process in an ISO class 5 clean room and is certified to pass ISO 10993-5 biocompatibility testing.

Advantages

- Improved Cleaning Productivity. Open-cell, large surface area foam enhances the ability to capture and remove foreign materials including metallic particles, excess adhesives, epoxies, liquid silicones, and fibers that result in lengthy and expensive inspection and rework procedures for medical device manufacturers.

- Lint-Free Wiper. Open-cell, abrasion resistant polyurethane foam eliminates wiping related lint generation.

- Improve Sanitization. CleanWIPE’s uniform, super fine pore structure and super soft conformable foam evenly applies alcohol to work surfaces and medical devices.

- Non-cytotoxic. Available certified non-cytotoxic and lot traceable to comply with FDA standard for the Medical Device industry.

- Compatible with medical silicones, adhesives and epoxies. High purity formulation and multistage washing process ensure wiper is free of Amines, Sulphur and Chloride to ensure compatibility with the curing of platinum cured silicones, adhesives and epoxies.

- Assured Quality. CleanWIPE foam wipers are produced, washed, and packaged in an integrated ISO class 5 facility that employs a ISO 13485 quality system. All products are LOT tested and traceable to raw materials.

|

|

UltraSOLV

Super Absorbent Cleanroom Sponge for ISO7 HT4666

UltraSOLV® is a highly absorbent, Class 10 Wiper constructed from a naturally reticulated, hydrophilic, polyurethane foam.

Using Foamtec’s patented cleaning process and foam technology, UltraSOLV® Wipers are ideal for cleaning critical tools and assemblies.

Available as a sponge for use with UltraSOLV® ScrubPADs on wet cleans.

|

|

|

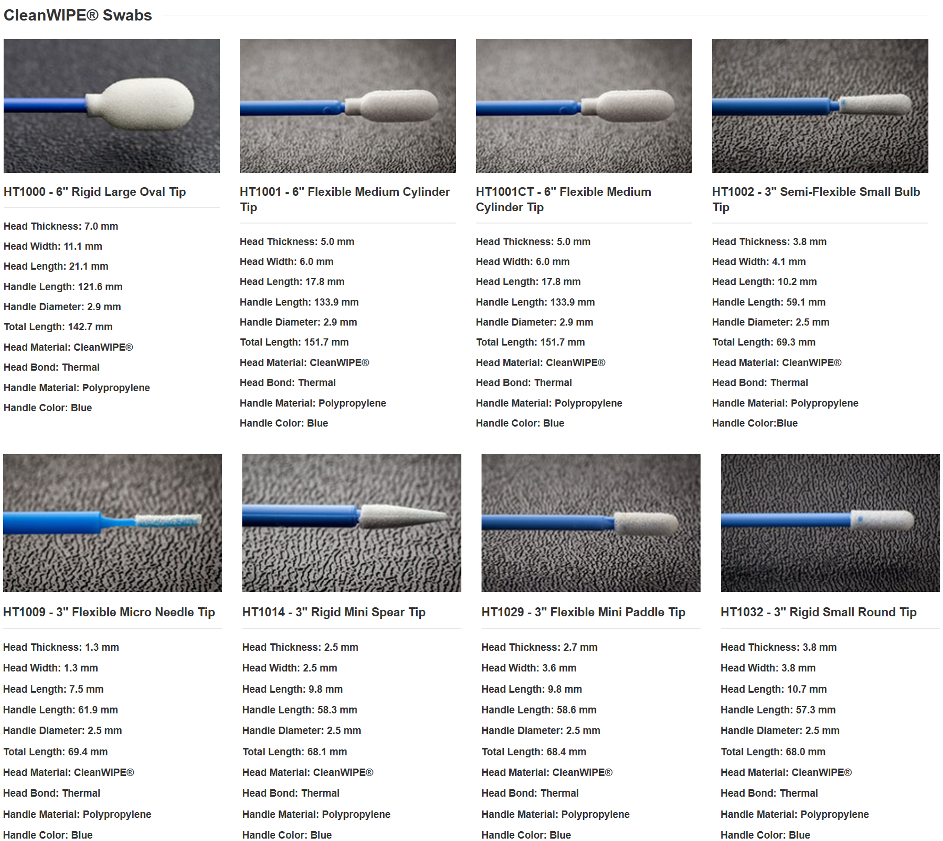

CleanWIPE®Swab

for cleanroom precision cleaning

|

|

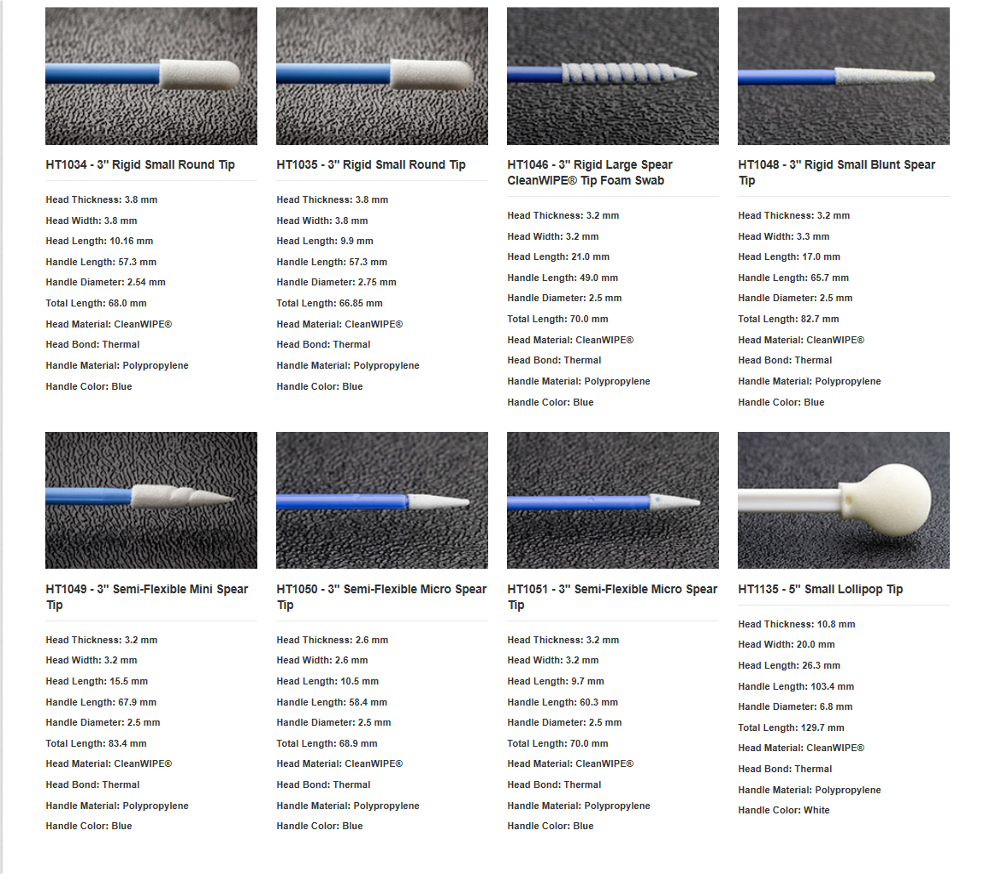

Sahara® Sponge

Scratch-Free Equipment Cleaning

|

|

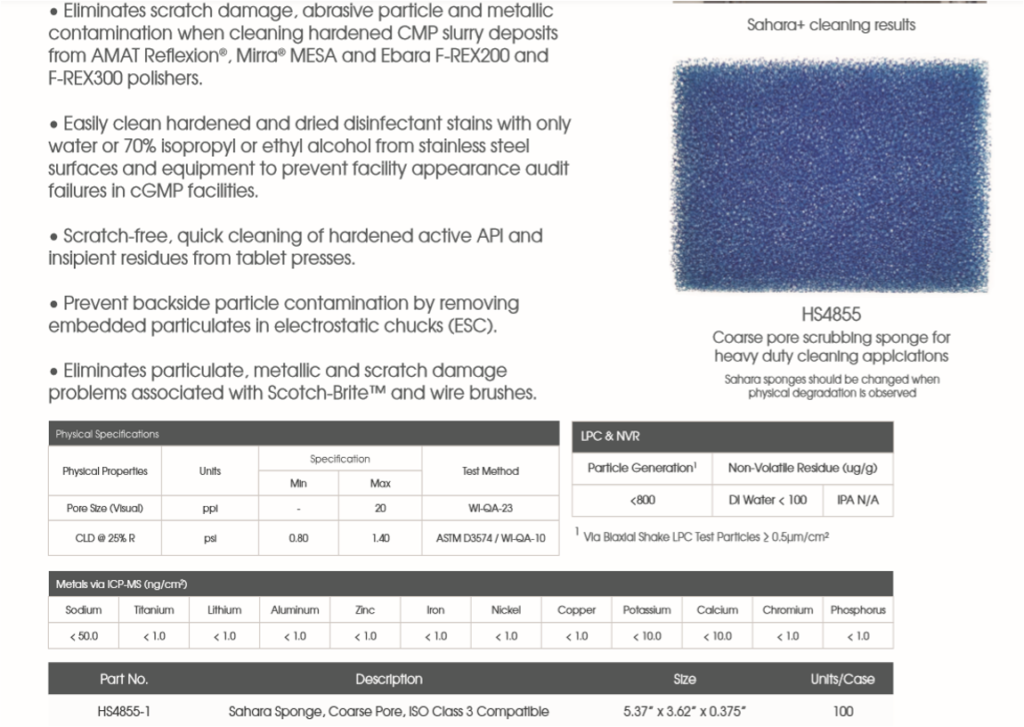

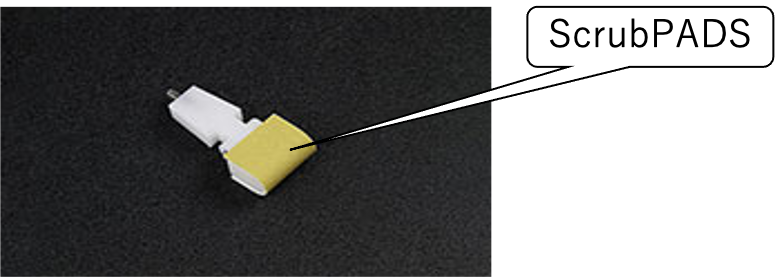

ScrubPADS®

Reduce Cleaning Time & Post PM Particle Levels in Hi-Vacuum Chambers

ScrubPADS® are patented wet-dry coated abrasives designed to clean residue, rust and by-product from process tools in semiconductor wafer fabs. ScrubPADS® are widely used in 200mm and 300mm fabs to PM or wet clean CVD, PECVD, dry etch, PVD and ion implant tools. ScrubPADS® are processed to be extremely low in metals and mobile ions and are available in a wide variety of diamond, silicon carbide and aluminum oxide abrasives to enable safe and efficient wet clean BKMs. ScrubPADS®, used in conjunction with UltraSOLV® Sponges, Wipers, and Swabs, reduce cleaning times, pump down times and contamination levels for critical process tools.

ScrubPADs are now available for ErgoWRENCH and ScrubWRIGHT to speed up cleaning for scratch sensitive and hard to reach areas of Vacuum Chambers.

Key Features

- Wide grit selection allows for quick removal of process-induced residue from aluminum, stain less steel, ceramic, glass, quartz and anodized surfaces while minimizing tool wear.

- The fiber-free construction of ScrubPADs greatly reduces particle levels in cleaned tools.

- By using washed abrasives, harmful ionic residues are minimized.

- Unique bonding technology minimizes the release of abrasive particles leading to cleaner PM procedures.

- Enables the elimination of H2O2 from PMs, which greatly reduces recovery times.

- Clean and unload with UltraSOLV® Sponge for longer life.

|

|

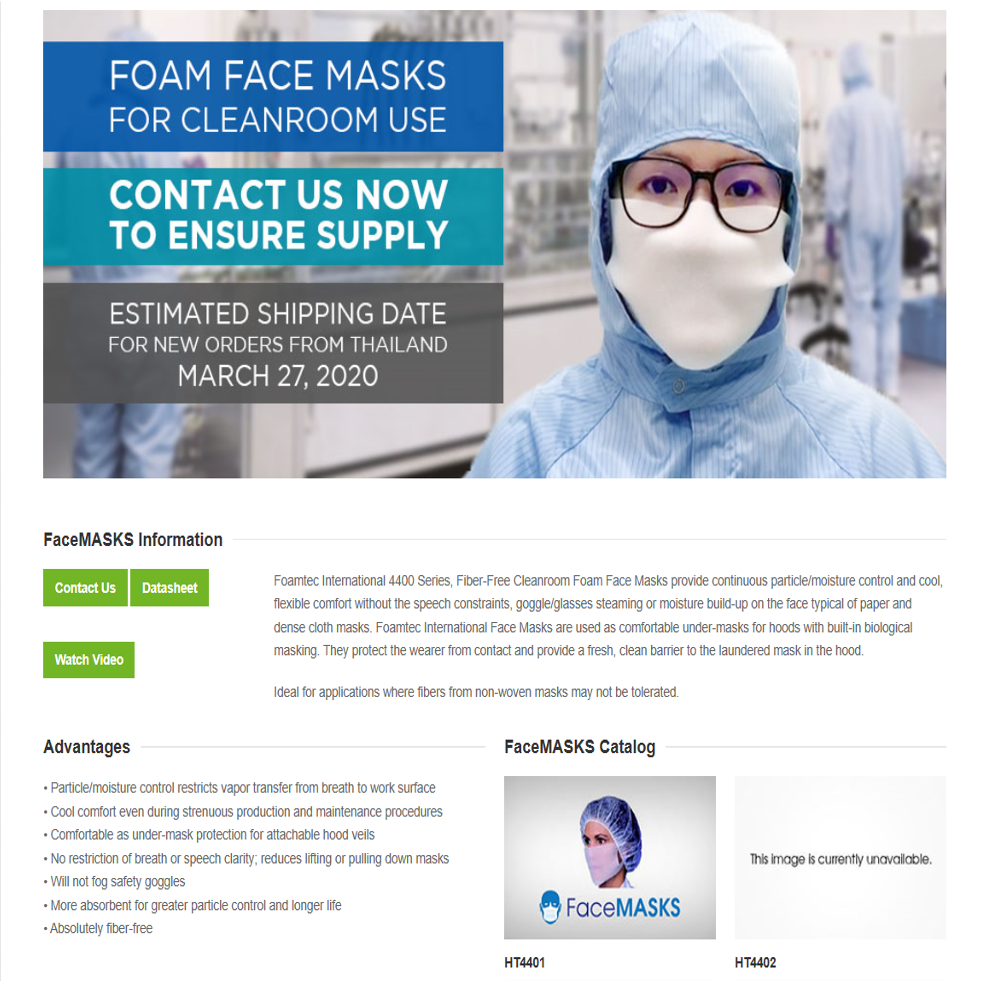

FaceMASKS

Fiber-Free Cleanroom Foam Face Masks

oamtec International 4400 Series, Fiber-Free Cleanroom Foam Face Masks provide continuous particle/moisture control and cool, flexible comfort without the speech constraints, goggle /glasses steaming or moisture build-up on the face typical of paper and dense cloth masks.

Foamtec International Face Masks are used as comfortable under-masks for hoods with built-in biological masking. They protect the wearer from contact and provide a fresh, clean barrier to the laundered mask in the hood. Ideal for applications where fibers from non-woven masks may not be tolerated.

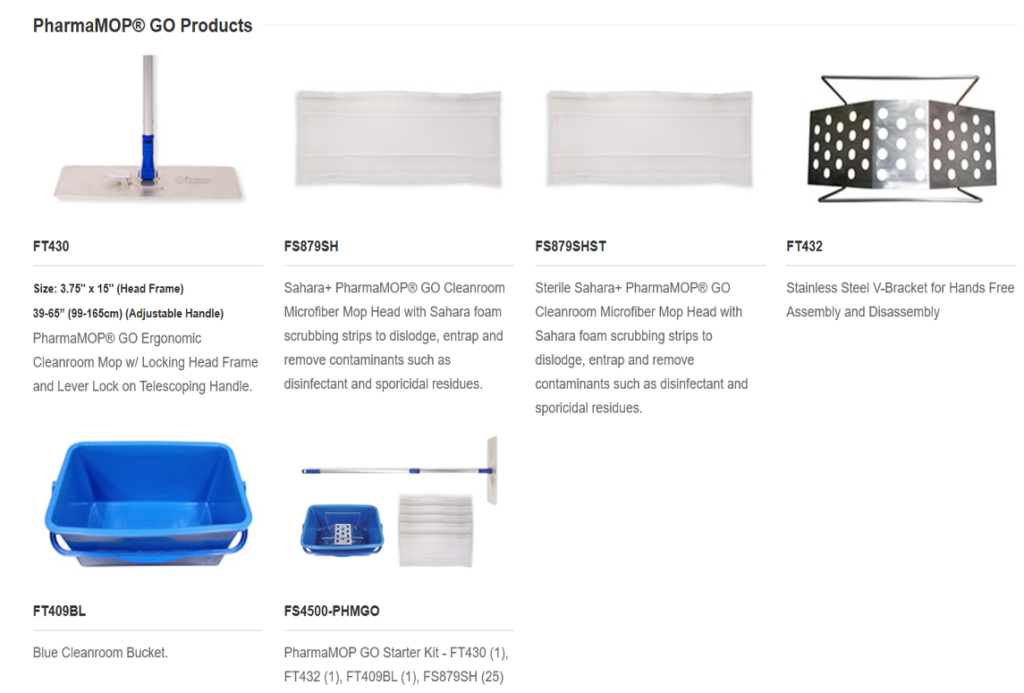

PharmaMOP®

PharmaMOP® is designed for cleanroom cleaning SOP’s. The light weight, 360 degree rotating and locking mop head give operators excellent control cleaning floors, walls and ceilings. The ultra-light handle , wringer less bucket system and drip resistant mop heads allow operators to efficiently carry out SOP’s with improved ergonomics.

|

|

Packing Information

| Products | Package | Carton and weight |

MiraWIPE®

|

150pcs/pack 8pack/carton 1200pcs/8pack(carton) |

26x44x26cm 10Kg |

CleanWIPE®

|

<HT4203> 25pcs/pack 40pack/carton 1000pcs/40pack(carton) |

64x33x48 ㎝ 5Kg |

UltraSORB®

|

<HT4666> 50pack/carton 2500pcs/50pack/carton |

76x46x46㎝ 15Kg |

Swabs®

|

tbd | |

Sahara® sponges®

|

tbd | |

Scrub PADS®

|

<HT4528> 10pcs/pac 10pack/big pack 100pcs/10pack/bigpack |

20x20x12.7cm 2Kg |

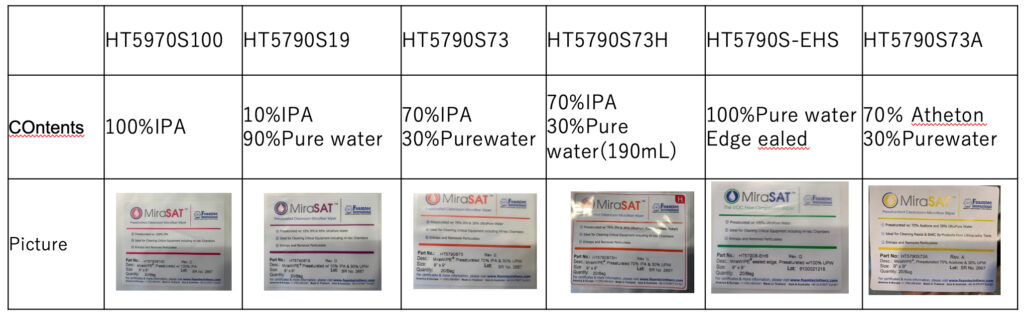

MiraSAT

The VOC Free Cleanroom Wiper

MiraSAT™ UPW is the first cleanroom wiper presaturated with 100% UltraPure Water designed to reduce VOC’s in advanced wafer fabs. MiraSAT™ now makes it possible to achieve IPA like cleaning efficiency without the costs and safety issues related to flammable solvents. MiraSAT™ is a no compromise cleanroom/EH&S wiping solution.

|